Signal Hound VSG25A & Spike Software Integration: Application Case in 5G Sub-6 GHz Device Testing

Signal Hound VSG25A & Spike Software Integration: Application Case in 5G Sub-6 GHz Device Testing

In the R&D process of 5G Sub-6 GHz terminal devices (such as smartphones, CPEs, and industrial IoT modules), efficient and accurate signal generation and real-time analysis are critical to accelerating product iteration. A medium-sized wireless communication equipment manufacturer faced challenges in its 5G device testing workflow: traditional test setups required separate operation of signal generators and spectrum analyzers, leading to cumbersome parameter synchronization, delayed data feedback, and low test efficiency. To address these pain points, the manufacturer adopted the Signal Hound VSG25A vector signal generator, which is deeply integrated with Spike RF analysis software, forming a unified test platform for 5G Sub-6 GHz device performance verification. This case details how the seamless integration of VSG25A and Spike software optimizes the testing workflow and improves R&D efficiency.

1. Background & Challenges

The manufacturer was developing a 5G Sub-6 GHz industrial IoT module supporting the 3.5 GHz band (N78) and 4.9 GHz band (N79), targeting smart factory wireless communication scenarios. During the R&D testing phase, the team encountered three key challenges:

• Complex Test Setup & Parameter Synchronization: The previous test setup used discrete signal generators and spectrum analyzers from different vendors. Engineers needed to manually configure signal parameters (frequency, modulation type, power) on the signal generator and separately set analysis parameters (span, RBW, demodulation mode) on the spectrum analyzer. This not only increased operation complexity but also easily caused parameter mismatch, leading to inaccurate test results.

• Low Real-Time Feedback Efficiency: When optimizing the IoT module’s receiver sensitivity and demodulation performance, engineers needed to repeatedly adjust signal parameters and observe the analysis results. The discrete setup required switching between two sets of software interfaces, resulting in a long feedback cycle (each parameter adjustment and result verification took about 15 minutes), seriously slowing down the R&D iteration speed.

• Difficult Data Correlation & Reporting: Test data from the signal generator and spectrum analyzer were stored separately, requiring manual collation and correlation analysis. This not only increased the workload of data processing but also easily led to data loss or errors, affecting the accuracy of test reports and the reliability of product performance evaluation.

The manufacturer urgently needed a test solution that could realize unified control of signal generation and analysis, real-time parameter adjustment and feedback, and automatic data integration. After evaluation, the Signal Hound VSG25A vector signal generator (paired with the SA124B spectrum analyzer) and Spike software were selected, leveraging their deep integration advantages to build an efficient 5G test platform.

2. Integration Solution Design

The core of the solution lies in the seamless integration between VSG25A and Spike software, which realizes unified control, parameter synchronization, and data co-analysis of the signal generation and analysis links. The specific test setup and integration logic are as follows:

2.1 Hardware Setup

The test system consists of four core components: Signal Hound VSG25A vector signal generator, Signal Hound SA124B spectrum analyzer, DUT (Device Under Test: 5G industrial IoT module), and a Windows 10 workstation. The VSG25A is connected to the workstation via USB 3.0 for power supply and data communication; the SA124B is also connected to the workstation via USB to realize real-time collection of the DUT’s transmitted signals and the VSG25A’s output signals; the VSG25A’s RF output port is connected to the DUT’s RF input port (via a 20 dB attenuator to protect the DUT), and the DUT’s RF output port is connected to the SA124B’s RF input port. This forms a closed-loop test system covering signal generation, DUT transmission, and signal analysis.

2.2 Software Integration Core Advantages

Spike software serves as the unified control center, realizing three key integration functions with VSG25A:

• Unified Parameter Configuration: Engineers can set both VSG25A’s signal generation parameters (frequency, modulation type, output power, bandwidth) and SA124B’s analysis parameters (center frequency, span, RBW, demodulation standard) in a single Spike interface. When switching test bands (e.g., from N78 to N79), the software automatically synchronizes the center frequency and bandwidth parameters of the VSG25A and SA124B, avoiding manual errors.

• Real-Time Data Co-Display: Spike software simultaneously displays the VSG25A’s output signal waveform, the DUT’s received signal demodulation results (EVM, BER), and the DUT’s transmitted signal spectrum in the same interface. Engineers can adjust the VSG25A’s signal parameters (such as adding channel noise, adjusting modulation order) in real time and observe the changes in the DUT’s performance indicators immediately, realizing instant feedback.

• Automatic Data Recording & Reporting: The software automatically correlates and records the VSG25A’s configuration parameters, SA124B’s analysis data, and the DUT’s performance indicators. It supports one-click export of test reports in CSV/Excel format, including parameter settings, test results, and waveform screenshots, greatly reducing manual data processing workload.

3. Implementation Process & Key Test Scenarios

The team used the integrated VSG25A-Spike system to complete two core test scenarios of the 5G industrial IoT module: receiver sensitivity testing and demodulation performance testing under complex signal conditions. The specific implementation process is as follows:

3.1 Receiver Sensitivity Testing

1. Unified Parameter Configuration in Spike: Engineers opened Spike software and selected the "5G NR" test mode. In the integrated control panel, they set the VSG25A’s output signal parameters: frequency = 3550 MHz (N78 band), modulation type = QPSK, channel bandwidth = 100 MHz, and initial output power = -100 dBm. Simultaneously, the software automatically configured the SA124B’s analysis parameters: center frequency = 3550 MHz, span = 120 MHz, RBW = 100 kHz, and demodulation standard = 3GPP TS 38.101.

2. Step-by-Step Power Adjustment & Real-Time Monitoring: Through Spike’s "Auto Power Sweep" function, the software controlled the VSG25A to gradually increase the output power in 1 dB steps. At each power level, Spike real-time displayed the DUT’s received signal strength (RSRP) and bit error rate (BER) through the SA124B’s data collection. When the BER dropped to 1e-6 (the standard threshold for receiver sensitivity), the software automatically recorded the corresponding VSG25A output power as the receiver sensitivity value.

3. Data Recording & Report Generation: After the test, Spike automatically generated a sensitivity test report, including the power sweep curve, the final sensitivity value (-98 dBm), and the corresponding RSRP and BER data. The report could be directly used for R&D evaluation without manual collation.

3.2 Demodulation Performance Testing Under Complex Signals

To simulate the complex 5G signal environment in smart factories (with multi-path interference and noise), the team used the integrated system to generate composite signals and test the DUT’s demodulation performance:

4. Complex Signal Generation via Spike: In Spike software, engineers configured the VSG25A to generate a 5G NR composite signal containing the main signal (3550 MHz, 64QAM) and two interfering signals (3555 MHz and 3545 MHz, each with a power 10 dB lower than the main signal). They also added AWGN (Additive White Gaussian Noise) to the signal via Spike’s built-in noise generation function, setting the signal-to-noise ratio (SNR) to 15 dB.

5. Real-Time Demodulation Analysis: The VSG25A output the composite signal to the DUT, and the SA124B collected the DUT’s demodulated output signal. Spike software real-time analyzed the error vector magnitude (EVM) of the DUT’s output signal (a key indicator of demodulation performance) and displayed the EVM distribution map in the same interface as the VSG25A’s signal configuration parameters. When engineers adjusted the SNR of the VSG25A’s output signal (e.g., reducing it to 10 dB), they could immediately observe the change in EVM (from 3.2% to 5.8%) in Spike, realizing real-time feedback on the DUT’s anti-interference performance.

6. Parameter Optimization & Retesting: Based on the real-time analysis results, the R&D team adjusted the DUT’s internal demodulation algorithm parameters and used the integrated system to retest immediately. The unified interface and parameter synchronization function allowed each optimization iteration to be completed in 3 minutes, significantly accelerating the algorithm tuning process.

3. Results & Value Delivered

The seamless integration of VSG25A and Spike software brought significant improvements to the manufacturer’s 5G device R&D testing workflow:

• 60% Improvement in Test Efficiency: The unified parameter configuration and real-time data feedback reduced the time for each test iteration from 15 minutes (discrete setup) to 6 minutes. The receiver sensitivity test for two bands (N78 and N79) was completed in 2 hours, compared to 5 hours with the previous setup.

• Reduction in Human Errors: The automatic parameter synchronization between VSG25A and SA124B eliminated parameter mismatch errors, reducing test result deviation from ±3 dB to ±0.5 dB. The automatic data recording and reporting function also reduced data processing errors by 90%.

• Accelerated R&D Iteration: The real-time feedback of demodulation performance under complex signals enabled the R&D team to complete the optimization of the DUT’s demodulation algorithm in 1 week, compared to the previous 2 weeks. This shortened the overall R&D cycle of the 5G industrial IoT module by 30%.

• Lower Test Cost: The integrated VSG25A-Spike system replaced the need for multiple high-cost discrete instruments, reducing the initial test equipment investment by 40%. At the same time, the simplified operation reduced the training cost for test engineers, as they only needed to master one software interface instead of multiple.

4. Key Insights & Conclusion

This case demonstrates the core value of the seamless integration between Signal Hound VSG25A and Spike software: it breaks down the barriers between signal generation and analysis in traditional test workflows, realizing unified control, real-time feedback, and automatic data integration. For 5G device R&D teams, this integration not only improves test efficiency and accuracy but also accelerates product iteration and reduces R&D costs.

Beyond 5G Sub-6 GHz testing, the VSG25A-Spike integrated solution can also be applied to Wi-Fi 6E/7, IoT, and other wireless communication device testing scenarios. Its user-friendly operation and efficient workflow optimization make it an ideal choice for small and medium-sized manufacturers, academic research labs, and R&D teams with high requirements for test efficiency and cost control. The success of this case further confirms that the deep integration of hardware and software is an important trend in modern RF testing, bringing tangible value to the wireless communication R&D ecosystem.

Recently Posted

-

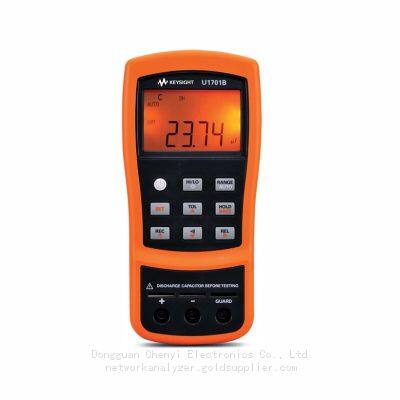

Application Scene Showdown: c E4980B vsE4980BL

December 25, 2025Application Scene Showdown: Keysight E4980B vs. E4980BLKeysight’s E4980B and E4980BL precision LCR meters excel in distinct applic Read More

Read More -

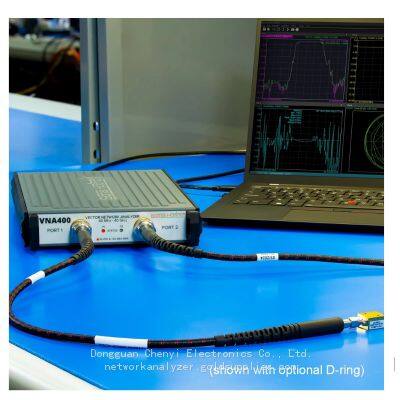

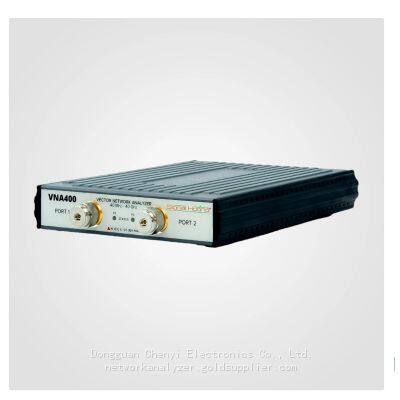

Signal Hound VNA400 Product Promotion Highlights

December 25, 2025Signal Hound VNA400 Product Promotion HighlightsCore Positioning: Cost-effective professional vector network analyzer, redefining Read More

Read More -

Signal Hound c: Real-World Application Cases Across Industries

December 25, 2025Signal Hound VNA400: Real-World Application Cases Across IndustriesThe Signal Hound VNA400, a high-performance yet cost-effective Read More

Read More -

Signal Hound VNA400 : Unmatched Cost-Performance Advantages in Vector Network Analysis

December 25, 2025VNA400: Unmatched Cost-Performance Advantages in Vector Network AnalysisVector Network Analyzers (VNAs) are indispensable tools in Read More

Read More